At Legacy Chiller Systems, we encourage and welcome suggestions and feedback. This is particularly helpful when it comes to our in-place screen and PLC updates, which is the ability to update the control interface (screen) and / or the programmable logic controller without needing to remove these devices from the chiller. A common method is to […]

VPN: Added Control Without Compromising Security

There is a trend in the industry for a higher level of control of process cooling equipment. However, the amount of control offered correlates directly with the amount of security needed, which in the past has caused problems where there is a lack of security. There needs to be a balance of remote control capability […]

Internet Remote Access: How It Helps!

In this installment of the Buyers Guide Series, Martin King talks about the Internet Remote Access feature that comes standard in all of our process chillers. Internet access is different from intranet access because the chiller can be controlled from anywhere, not just within the work site’s network. This feature can be particularly helpful when […]

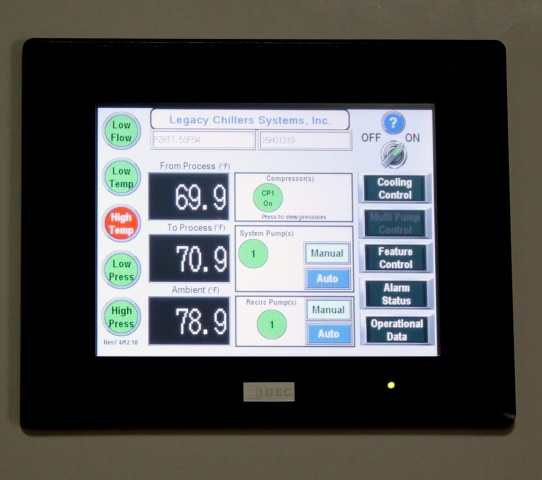

We Are On the Technician’s Team: Highly Visible User Interface

When it comes time to maintenance or repair a process chiller, that usually means you’ve got to get on a hot, bright roof. There’s nothing more frustrating than trying to read the tiny numbers on the dark screen, with the glare of the sun. We are on the technician’s team, and we’re always looking for […]

How To Prevent Leaks in a Process Chiller: Machine Bent Copper Tubing!

Before we allow our process chillers to go into the field, entrusting them to consistently and effectively perform, we put them through the ringer. We apply a series of conditions, harsher than the ones they should ever actually encounter, and see if they break. We look for any errors in the manufacturing process that we […]

Process Chiller Buyer’s Guide: Evaporators!

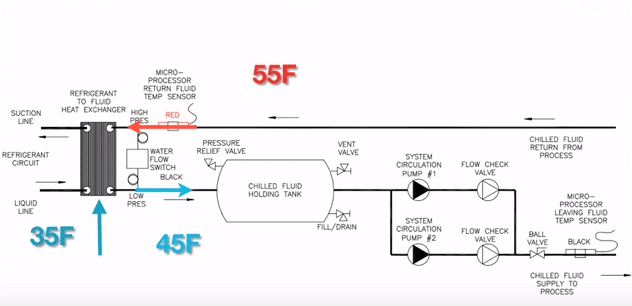

Process chillers have two sides: the process water side, and the refrigerant gas side. The heat is picked up from the process on the process water side, and gets transferred to the refrigerant side, where it is removed to air or water. In between these two sides is the evaporator, sometimes called the chiller barrel. […]

Pump It Up: Why Legacy Chillers Uses Gould’s Pumps Exclusively

Process chillers have a pretty simple job: To remove heat from places and processes that produce too much of it. They move the heat (BTUs) from one place to another. While the goal might be straightforward, the process that chiller systems go through to get the job done is comprised of many aspects. It really […]