It’s official: Legacy Chiller Systems has been around for twenty years. The company has survived a series of recessions and changes in the industry, while still developing new technologies and expanding its market, all thanks to one man: Martin King. As the founder, CEO, and president of the company, Martin has quite a story to […]

Process Chiller Buyer’s Guide: Evaporators!

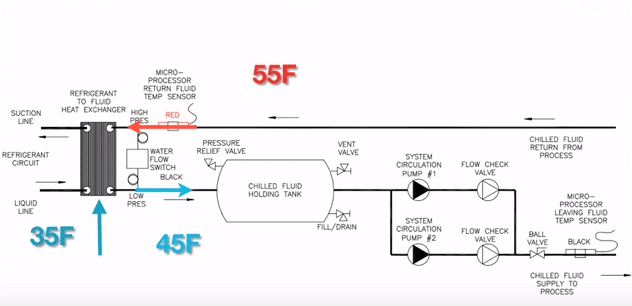

Process chillers have two sides: the process water side, and the refrigerant gas side. The heat is picked up from the process on the process water side, and gets transferred to the refrigerant side, where it is removed to air or water. In between these two sides is the evaporator, sometimes called the chiller barrel. […]

Unique Process Chiller Applications: The Celeste Bartos Film Preservation Center

Most of the time, process chillers are used for applications that are… less than interesting. While completely necessary to a myriad of operations, process chillers aren’t usually involved in engaging conversations, until now! Since the start of the digital age, we have all become accustomed to video formats being discussed in terms of 720, 1080, […]

Pump It Up: Why Legacy Chillers Uses Gould’s Pumps Exclusively

Process chillers have a pretty simple job: To remove heat from places and processes that produce too much of it. They move the heat (BTUs) from one place to another. While the goal might be straightforward, the process that chiller systems go through to get the job done is comprised of many aspects. It really […]

Our Process Chiller Buyer’s Guide Just Got Better

At Legacy Chiller Systems, we understand that purchasing a process chiller isn’t something that very many people do, and hopefully isn’t something that they have to do more than once! We believe that the easiest way to help the customer make this somewhat technical decision is to equip them with the knowledge and facts necessary […]

Behind The Scenes With The Team

Cheerful people doing quality work: that’s what Legacy Chillers Systems’ factory contains. This video is a compilation of the team that manufactures Legacy chillers, showing some of the metal punching process, the brazing, and the electrical wiring. Always with a smile, the team performs consistent quality, on time.